The Evolution of Laser Cutting Technology: A Look into the Future

In the realm of manufacturing, laser cutting has become a go-to technology for precise and efficient material processing. Over the years, advancements in laser cutting technology have transformed the industry, revolutionizing metal fabrication processes. In this blog post, we will delve into the evolution of laser cutting technology and take a glimpse into the future, exploring the possibilities of this incredible technology.

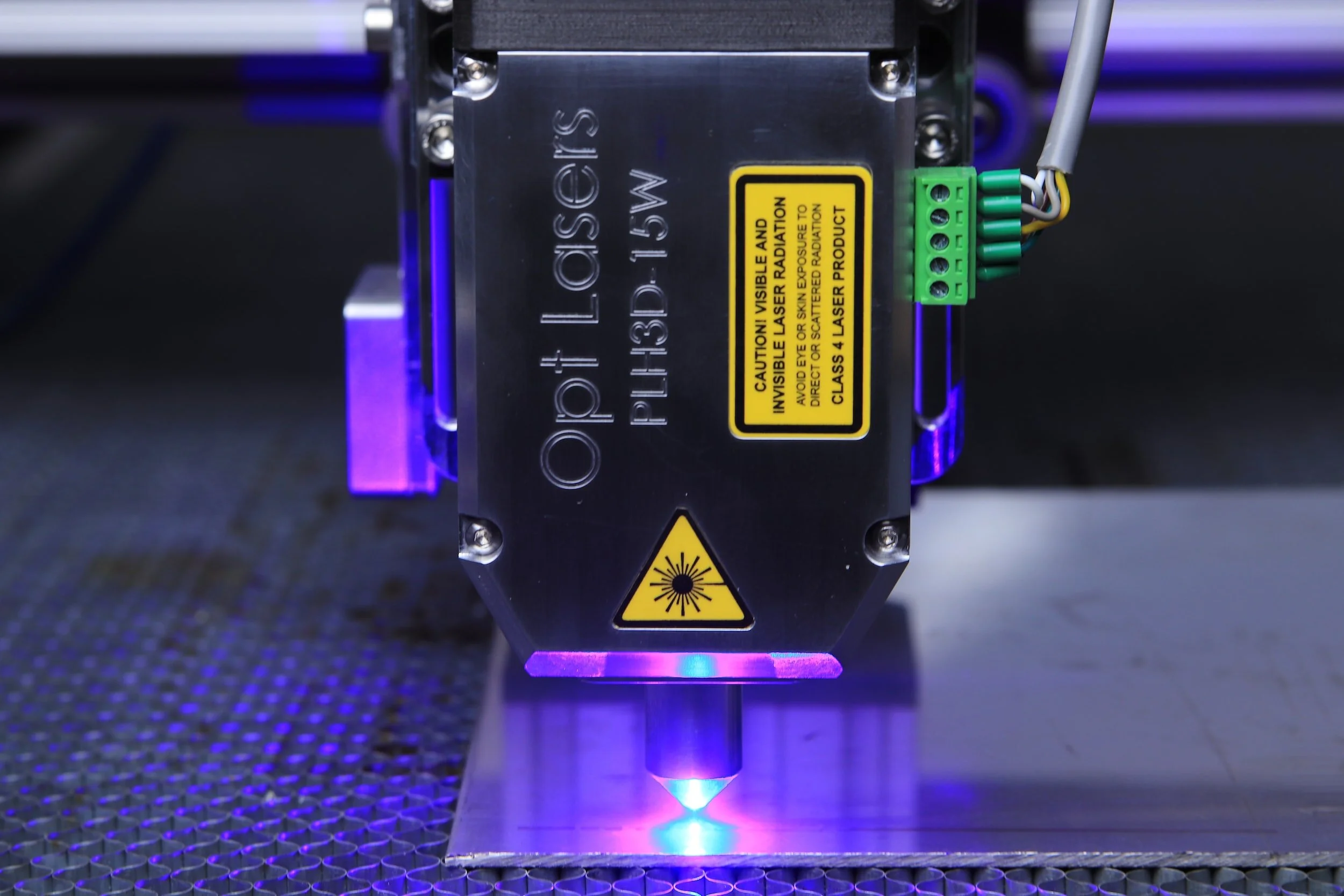

Laser cutting is a process that employs a focused beam of light to cut through materials with remarkable precision. When it comes to metal laser cutting, the technology has proven to be a game-changer. The intense heat generated by the laser beam vaporizes or melts the metal, resulting in clean, precise cuts without any physical contact. This non-contact cutting method eliminates the need for conventional cutting tools and reduces the risk of material distortion or damage.

The evolution of laser cutting technology has led to significant improvements in precision, power, and versatility. As lasers have become more powerful and efficient, the cutting speeds and capabilities have increased exponentially. Modern laser cutters can effortlessly slice through a wide range of metals, including stainless steel, aluminum, and carbon steel, with utmost accuracy. This level of precision allows manufacturers to achieve intricate designs and complex shapes that were once considered unattainable.

One area where laser cutting technology has witnessed significant advancement is in the power output of the laser cutters. Higher wattage laser cutters, such as 12kW and beyond, have become more prevalent. These machines offer exceptional cutting capabilities, enabling them to handle various metal thicknesses, from thin sheets to thick plates, with ease. The increased power output also results in faster cutting speeds, leading to improved productivity and reduced manufacturing costs.

As laser cutting technology continues to evolve, the focus is shifting towards automation and integration. Laser cutters are now equipped with advanced computer numerical control (CNC) systems, enabling precise programming and automation. This allows for complex designs to be replicated consistently and efficiently, ensuring high-quality output every time. Additionally, the compatibility of laser cutters with computer-aided design (CAD) software streamlines the production process, further enhancing precision and efficiency.

Looking into the future, the evolution of laser cutting technology shows no signs of slowing down. Research and development efforts are underway to explore new possibilities and push the boundaries of what laser cutters can achieve. Advancements in laser sources, such as fiber lasers and ultrafast lasers, are expected to offer even greater precision, power, and versatility.

One area where future advancements may occur is in the development of hybrid laser cutting systems. These systems combine laser cutting with other complementary technologies, such as waterjet cutting or abrasive cutting. By integrating different cutting methods, manufacturers can benefit from the advantages of each technology and expand their capabilities to meet a broader range of material processing requirements.

Another area of interest is the development of intelligent laser cutting systems. These systems leverage artificial intelligence and machine learning algorithms to optimize cutting parameters, monitor and adjust in real-time, and improve overall efficiency and quality. The ability to analyze vast amounts of data and make informed decisions opens up new possibilities for precision and productivity in laser cutting processes.

In conclusion, the evolution of laser cutting technology has revolutionized the metal fabrication industry, unleashing precision and power like never before. With advancements in power output, automation, and integration, laser cutters have become indispensable tools for manufacturers worldwide. Looking ahead, the future of laser cutting holds immense promise. From hybrid systems to intelligent automation, the possibilities are endless. As technology continues to advance, we can expect even greater precision, efficiency, and versatility in laser cutting, empowering manufacturers to achieve new heights of productivity and creativity.